This article presents a remarkable manganese mobile crushing and screening project in Johannesburg, South Africa. The project is set in an open - pit mining area, which meets the specific needs of the local mining environment.

The processing capacity of this project ranges from 200 to 250 MTPH. The processing flow starts with an excavator, followed by a feeder, a primary jaw crusher, screening, and then a secondary HP cone crusher. The raw material is manganese ore with a 40% grade, and the primary feeding size is 720mm. The finished product size is - 40mm, which is well - received by the market in China through a combined transport mode of train and shipping.

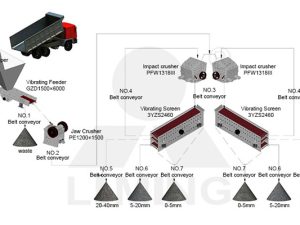

For the configuration, two sets of mobile crushers are deployed. The primary mobile jaw crushing station is equipped with GZD1300×4900 and Jaw Crusher PEW860. The secondary mobile cone crushing & screening station consists of HPT300 and Vibrating Screen 3YZS1860. A Siemens electric control cabinet is also included to ensure stable operation, along with a belt conveyor for material transfer.

After commissioning in 2015, the equipment has been running stably, and the final products fully meet the customer's requirements. The customer is highly satisfied with the outcome. Liming offers a wide range of crushing, grinding, and beneficiation solutions. If you are interested in similar projects, feel free to contact us for more detailed information. This successful project in Johannesburg can serve as a good reference for future manganese processing endeavors.